Prime costs ad conversion costs are different in their calculation, presentation and objective. Process costing is used when a company produces large volumes of identical units (e.g., in chemical processing or food production). The only direct material added in the packaging department for the 5A sticks is packaging. The packaging materials are added at the beginning of the process, so all the materials have been added before the units are transferred out, but all of the conversion elements have not.

How to Calculate Conversion Costs?

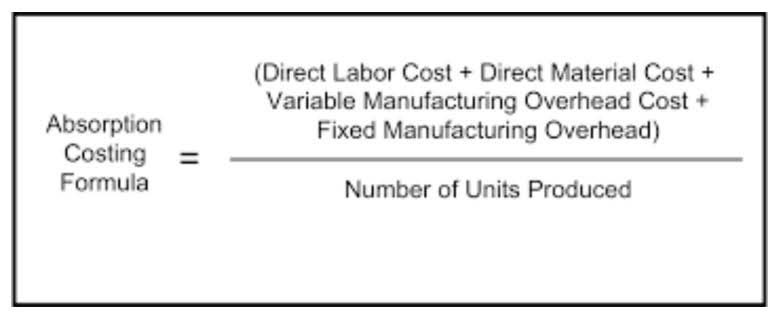

The true cost a company uses in the process of turning raw materials into finished goodsincludes both overhead and direct labor. Managerial accountants and production managers measure these conversion costs to estimate production expenses, develop product-pricing retained earnings models, and estimate the value of finished inventory. Managers also use these costs to evaluate the efficiency of the production process and identify waste. The total materials costs for the period (including any beginning inventory costs) is computed and divided by the equivalent units for materials. The total of the cost per unit for material ($1.17) and for conversion costs ($2.80) is the total cost of each unit transferred to the finishing department ($3.97). In accounting, conversion costs represent the money spent on turning raw materials into finished products.

Q3. How can a company manage and reduce conversion costs?

Begin with a keyword double declining balance depreciation method audit to identify both high and low-converting keywords. Add low performers as negative keywords and allocate more budget to those driving conversions. Analyzing Cost Per Conversion across various campaigns identifies which strategies offer the most conversions for the least spend. Invest more in campaigns that effectively convert the target audience, drive more leads and customers into the sales pipeline, and positively contribute to the campaign’s overall performance.

Implementing Best Practices for Prime Cost Management with TranZact

As with calculating the equivalent units and total cost of production in the initial processing stage, there are four steps for calculating these costs in a subsequent processing stage. First, we need to know our total costs for the period (or total costs to account for) by adding beginning work in process costs to the costs incurred or added this period. Then, we compare the total to the cost assignment in step 4 for units completed and transferred and ending work in process to get total units accounted for. Calculating conversion costs is crucial for managing production expenses, setting competitive prices, and making informed decisions about scaling production or optimizing efficiency.

Accounting Principles

Conversion costs reflect a company’s total amount spent converting raw materials into fully-furbished products. It includes the direct labour costs and the amount spent on indirect factors like electricity bills, factory rent, etc., which cannot be directly traced down to the production of a single unit. Conversion costs are beneficial, especially for manufacturing businesses which have to deal with conversion on a large scale daily. They help the company to take important financial decisions and help them to bring efficiency to the production system.

Return on Ad Spend (ROAS) calculates the total revenue generated for each dollar spent on advertising. Cost Per Lead (CPL) is a digital marketing metric that quantifies a company’s cost to acquire a new lead. Cost per Acquisition (CPA) calculates the average spend on advertising for acquiring one customer.

- Direct labor costs consist of wages, salaries, and benefits like pensions and insurance for production employees.

- The calculator will then present the total conversion cost, which is the sum of the direct labor cost and the manufacturing overhead.

- Prime costs are a great tool to measure the efficiency of the production process.

- Additionally, we’ll explore how Sourcetable lets you calculate this and more using its AI powered spreadsheet assistant, which you can try at app.sourcetable.com/signup.

- In manufacturing, conversion costs are the expenses incurred to convert raw materials into finished goods.

- In such cases, it is time-saving to calculate equivalent units and unit costs by combining direct labor and manufacturing overheads instead of doing separate calculations for the two cost items.

- Learn how to harness AI to analyze data, uncover patterns, and craft personalized landing page strategies.

Manufacturing Overhead

The manufacturing sector analyses both prime costs and conversion costs to measure efficiency in the production of a product. In the table above, the direct labor costs for each employee are calculated by multiplying the total hours worked by the hourly wage rate and adding any additional benefits or allowances. The total direct labor cost for all employees is then summed up to obtain the overall direct labor cost for the specified period. If it is not, such as just one or two conversions from 1,000 clicks, consider pausing the keyword. You see which of your campaigns have the lowest cost per conversion, preferably compared to high values for those conversions, and focus your efforts and budget on them. Remember that you can define conversion however you want, such as the number of sales and number of operating leverage dol formula + calculator signups for your email list.

Upon completion, earn a recognized certificate to enhance your career prospects in finance and investment. Kenneth W. Boyd has 30 years of experience in accounting and financial services. He is a four-time Dummies book author, a blogger, and a video host on accounting and finance topics. This video conversion costs formula will provide a demonstration of cost assignment under the FIFO method.

You can have discussions with your marketing team regarding these non-profitable campaigns. Sourcetable is not limited to academic use; it excels in professional environments, where precision and efficiency are crucial. Whether you’re studying for school or crunching numbers at work, Sourcetable’s versatility and power make it an indispensable tool for anyone looking to enhance their analytical skills. Customer Acquisition Cost, commonly known as CAC, represents the total expenses a business incurs to acquire a new customer.